Product Briefing

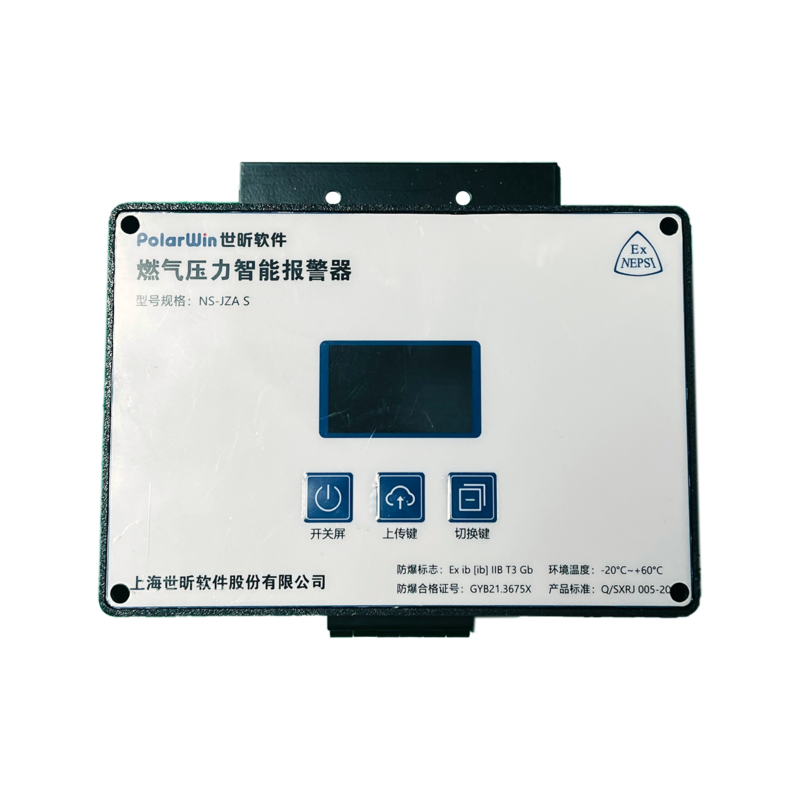

Gas regulator warning system consists of information collection end (gas regulator warning device), communication center end (telecommunication station), information terminal (PC,mobile) and alarm server. The information collection terminal collects the gas regulator site data and transmits the data directly from the early warning device to the designatedhost, and achieves the purpose of real-time remote monitoring of the gas regulator operating conditions through the dedicated server and monitoring terminal (PC, mobile). Pressure and alarm data can be viewed on-site through the device screen.

Matching with different transmitters can monitor: pressure, differential pressure, gas leakage concentration, pipeline internal temperature, flow, shut-off valve operation status, regulator cabinet dooropening and closing status and other data.

Technical Parameters

Pressure signal sampling accuracy level | Precision level≤0.5%FS |

Pressure signal acquisition interval | 1sec/time~9min/time |

Five-way pressure transmitter access |

|

Accuracy | 0.5 level |

Stability | 0.02%FS/year |

Communication mode | GSM +NB-IOT +wireless mobile communication network (GPRS) |

Current analog signal interface two | 4~20mA |

External communication port two (RS485 and TTL) | For external flow meter or computer |

Battery life | 1 year (detection frequency: every minute/time; upload data: every day/time; upper limit: 400 times/year) |

Explosion-proof grade | Ex ib IIB T3Gb |

Data storage capacity | Can store 300,000 monitoring values and corresponding time |

Number of read/write times (service life of storage components) | ≥1014 times |

Technical Parameters

1、Customizable power supply solution: according to customer needs to provide utility power, battery, solar power supply solutions.

2、Different from large SCADA system, easy to install, no need for utility power, low cost, support a variety of communication methods: GPRS, NB-loT, 4G.

3、Automatically collects data and generates data drawings, which not only facilitates data storage, but also reduces paper usage and saves energy and protects the environment.

4、Advance prevention through real-time alarms, extending the service life of the regulator and reducing the risk of gas use.

5、High efficiency, low maintenance costs, reduce the cost of corporate expenditures, with economic and social benefits.

6、Ensure the gas safety of gas users, and improve the service quality and management level of the gas industry.

7、Monitoring equipment can monitor and record data such as pressure, leakage, flow, differential pressure, temperature, cut-off status, etc., and complete the all-round monitoring of the regulator equipment throughout the whole life cycle.

Comprehensive monitoring of the regulator equipment, the whole life cycle.